Servicing an air compressor is moderately easy. It doesn’t necessarily require an HVAC technician, you can do it yourself if have adequate experience, and knowledge about fixing electrical motors, motor components, and about handling specialized tools.

Safety advice

Servicing air compressor requires you to follow safety procedures. Wear apron, hand gloves, safety goggles, and safety shoes. Do not test the pressurized air on your skin or on any other person. Check the motor and metallic parts for grounding. Clean the area you worked.

Necessary tools and materials for servicing air compressor

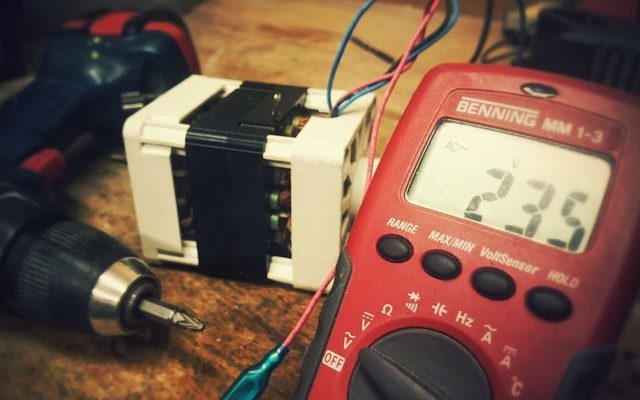

Flat screw driver, Phillips screw driver, open end wrench set, adjustable wrench, Allen key Set, Avo meter, Clip-on-meter, grease, WD-40 contact cleaner, cotton etc.

How to service an air-compressor the easy way

1. Check the oil indicator and maintain it to the required level (If any). Check the V-belt (if any).

2. Run the machine and fill it with pressurized air until the HPCO (High pressure Cut out) cuts the power.

3. Observe the pressure gauge.

4. Make sure all outlet valves are closed.

5. Switch OFF and unplug the air-compressor from power source.

6. Now, gently open the drain line valve located beneath the cylinder or at the side of the cylinder. Use proper tools to open it.

7. Let the pressurized air leave the cylinder with hissing sound. Some oily/greasy water like substances may get out with the air.

8. Now, close the drain valve smoothly. Check the seal (if any) and make sure it is properly fixed.

9. Look for the defective pipe joints and fix them.

10. Check the electrical plug, Contact points and wire of the electrical motor. Replace if found faulty/corroded. Spray little WD-40 contact cleaner on the connections.

11. Check the Air hose pipe. Replace it if it has leakage.

12. Check the tight fitting connection of Air hose with Air-gun/nozzle and outlet valves.

13. Run the electrical motor and check whether it is taking proper ampere or not. Also check the capacitor.

14. Observe the high pressure gauge while the machine is running and check whether the High pressure cut out stops the motor when pressure reaches the desired scale as per manual.

15. Clean the air filter (if any) and grease the wheels of the equipment.

16. Test run the machine, and check for its proper operation.